The Facts About Dust Extractor Vs Shop Vac Revealed

Table of ContentsAn Unbiased View of Dust Extractor Vs Shop VacThe 25-Second Trick For Dust Extractor Vs Shop VacDust Extractor Vs Shop Vac Things To Know Before You BuyGetting The Dust Extractor Vs Shop Vac To WorkWhat Does Dust Extractor Vs Shop Vac Mean?Not known Facts About Dust Extractor Vs Shop Vac

The difficulties for foundry dust collection systems focus on crystalline silica dust, carbon monoxide, as well as warmth, which are poisonous combinations. These elements make conference air quality requirements hard and also requiring. When selecting a dirt control system for a factory, the initial factor to consider is the ability of the unit to endure severe and hazardous office problems.Apart from the noticeable conditions, the selected equipment needs to meet the policies of OSHA, the EPA, and also the NFPA. To meet those standards, dust collection systems utilize shakeout enclosures, collection hoods, thaw, mold putting, cooling hoods, and exhaust stacks. Pleated bag and cartridge-style collection agencies have an extremely effective filtering system as well as a compact dimension and also decreased pressure drop.

Covering, or thermal spray, applies heated material to steels to coat their surfaces. Dirt collection systems for this kind of operation must be specifically made to fit the type of layer being applied. The purpose of the system is to manage as well as minimize overspray and also dirt. The typical thermal spray dirt control system uses ducts to relocate air to the collection gadget.

Fascination About Dust Extractor Vs Shop Vac

It would appear most likely to enhance air movement and also movement, this type of remedy may be ineffective and waste energy. The style of the cubicle depends on the pressure of the air entering the cell or booth. For most systems, it is essential to have a mild vacuum in the booth to stay clear of possible favorable stress.

Another method is just positioning the make-up air connection on the top of the booth. No matter the style, it is very important for the cleansing of the air to have cross ventilation. A lot like a cleanroom, airflow in a thermal spray booth can be either straight or downward, though the descending layout is best for dirt collection systems. dust extractor vs shop vac.

The pharmaceutical industry is an extremely regulated sector with comprehensive as well as exact laws. Dust from drugs is produced mainly during the production as well as product packaging of items - dust extractor vs shop vac. Each action of generating a medicine, that includes granulating, drying out, blending, pushing, finishing, as well as grinding, creates big amounts of dust that need to be eliminated.

Some Known Details About Dust Extractor Vs Shop Vac

HEPA filters are frequently discovered in pharmaceutical dust control systems since they are one of the most reliable and reputable. As with a foundry system, they are mounted as an additional security to achieve absolutely no discharges. Reusing produces a good deal of dirt as a natural end result of reducing products to their raw materials.

Dirt comes from after materials are shredded, squashed, or have paint or lacquer removed. All reusing facilities are required to abide by air quality criteria. As they work to fulfill high quality standards and control toxins, they have actually acknowledged that dust control is a significant problem, causing the large use dirt collection systems to mitigate and also include the trouble.

Not known Facts About Dust Extractor Vs Shop Vac

When manufacturers choose a dust control system, they are suggested by producers regarding the kind of system that would certainly best fit their demands considering that purchasing and setting up a dirt control system is a significant financial investment. Particle matter is available in a large selection of forms, from silicon dust to home wood chips as well as sawdust.

Below is a list of the kinds of bits that dirt collection systems can eliminate. Plaster Plaster needs a high-efficiency baghouse system with the ability of operating at temperatures near 428 F (220 C). Felt Felt is utilized in clothing manufacturing as well as calls for dust collection systems at 3 phases of the procedure.

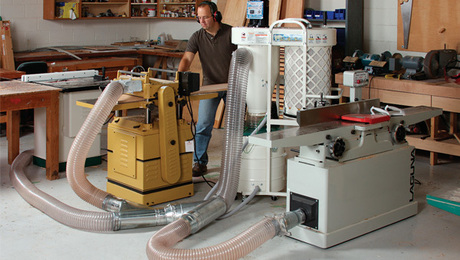

Steel Chips Grinding procedures generate metal chips that require to be eliminated for the safety and security of employees. Baghouses as well as scrubbers are made use of for airflow filtration. Sawdust This is the most usual product eliminated by dust collection systems. Cartridge or baghouse techniques can be made use of, with baghouse being one of the most efficient.

The smart Trick of Dust Extractor Vs Shop Vac That Nobody is Talking About

Fabric filter bags in a cartridge system are one of the most efficient technique for collecting dirt. Cement Concrete dust is developed during the motion and also transport of the item. Dust collection systems are covered to include the dirt and tidy the air. Clay Clay dirt is created in the manufacturing of bricks.

With the intro of dust collection systems, employees are safer as well as more secured. Sugar Sugar dirt is the spin-off of the manufacturing of candy. Pulse find out here now jet systems are utilized to maintain the filters of the dust collection system particulate-free. The accumulated product is removed as well as collected in drums. Zinc Zinc dust is created in the galvanizing procedure.

More About Dust Extractor Vs Shop Vac

A baghouse system is the preferred system. Rice Dust Rice dust has very fine and also minute particles that build up during the production of rice-based products. A dust collection system is required for the protection and safety and security of employees. Silica Silica is one of the most typical compounds in the world. It is a central part of several production procedures, such as the manufacturing of glass, ceramic tile, cement, as well as asphalt.